| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | PDV |

| Model Number : | PT-DZ80C , PT-DZ80R , PT-DZ80L |

| Payment Terms : | D/A, D/P, T/T |

| Price : | Negotiable |

| Delivery Time : | 1-2 weeks |

Z-Axis Upper And Lower Manual Lifting Table With Differential Head

DZ80

PT-DZ80 Z-axis manual translation table, product standard cross

ball guide, differential head drive. The main material is aluminum

alloy, with black anodic oxidation treatment on the surface, high

sensitivity, small size, moderate thickness of the table, and can

be used in single or multi-dimensional combination. It is suitable

for optical experiment and other fields requiring high precision of

manual adjustment.

Product features:

1. The cross roller guide rail is adopted, which has strong load

capacity and good wear resistance, ensures the sensitivity and

other key indicators of the product, and can realize high-precision

and smooth lifting movement.

2. The main body is made of aluminum alloy, with blackened surface

and light weight. It can be placed in other devices.

3. The products have rich dimensions, good compatibility, short

delivery time and high cost performance.

4. Using the decimeter card driving mode, each product is divided

into left, right and center. It is suitable for products used in

the vertical direction or z-axis. When combined, it is very

flexible and convenient.

Product parameters:

Specification | PT-DZ80C | PT-DZ80R | PT-DZ80L | |

Driving method | Micrometer Heads | |||

Operating position | center | right | left | |

Min Reading | 10μm/ scale | |||

countertop | 80*80mm | |||

Trip | ±12.5mm | |||

Rail | Cross Roller Guide | |||

Bearing | 5kgf(49N) | |||

Moving Accuracy | Straightness | 3μm | ||

flapping | 25’’ | |||

wagging | 15’’ | |||

Verticality | 80μm | |||

Verticality of motion | 30μm | |||

weight | 0.95Kg | |||

Surface treatment of materials | Black-Anodic Oxidation Treatment | |||

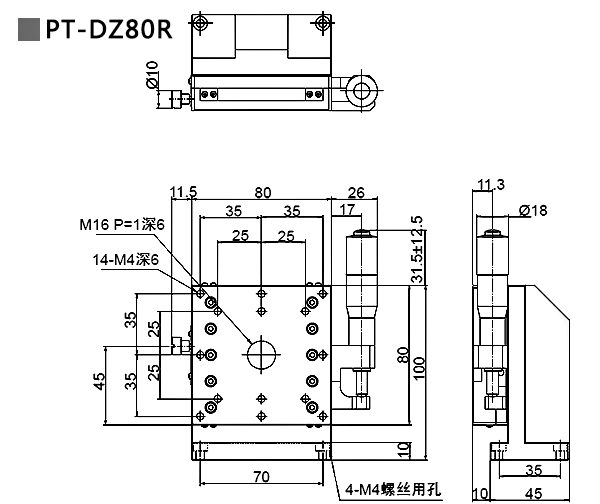

Product Dimension Map:

Manual lifting platform selection of cross roller guide rail

benefits

(1) Long service life, high rigidity.

Using the unique roller holding method, the effective contact

length of the roller has increased 1.7 times compared with the

traditional products, and due to the shorter pitch interval of the

roller, the number of rollers has increased by 2 times, and the

life of the roller can be obtained by 6 times. Therefore, safety

design can be fully considered for the vibration and impact of

linear moving parts.

(2) smooth movement.

In VR type, each roller is separated and maintained by the cage,

and because the roller bag in the cage is in surface contact with

the roller, there is good lubricating oil retention, so the wear is

small, can obtain smooth rolling motion.

(3) High corrosion resistance.

The VR and VB series also offer stainless steel models with

excellent corrosion resistance.

|